MES Qguar system for production management

Task delegation and control of production progress in real time.

- Komunikaty

- Wskaźniki

- Interfejsy

- RFID

- VOICE

Qguar MES (Manufacturing Execution System) is a manufacturing execution system that enables the user to model production processes in a fast and effective manner and to monitor the course of their realization. The system can:

- automatically transmit crucial information between production process participants,

- coordinate tasks performed by operators, foremen, planners and specialists from the process maintenance department,

- integrate with external systems (ERP, SCADA, logistic systems),

- trace products, components and raw materials at every stage of their life within a plant, beginning from order placement through the realization of production processes to shipment to a consignee.

Information about a production process collected by the MES system support the management based on the principles of “Lean Manufacturing”.

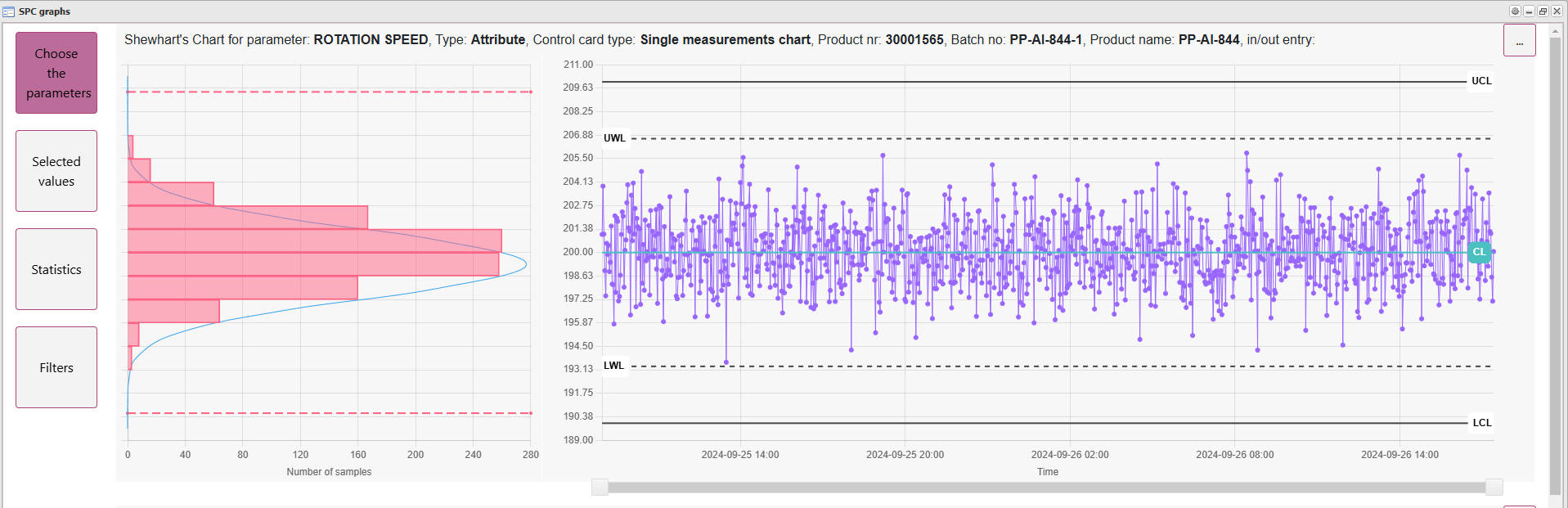

The MES system for manufacturing management supports such standards as ISO, HACCP, IFS, SIX SIGMA, among others. The MES program helps a company meet numerous requirements and regulations imposed on industrial branches, where product safety is the highest priority, which includes automotive, cosmetic or food industries.

Production supervision and reporting in MES Qguar system

Customizable, automatically generated reports provide a complete overview of events occurring in a production house at different levels of detail. The scope of a report may be adapted to the needs of a particular position, from a shift master to plant manager. This helps one identify bottlenecks and areas that require optimization.

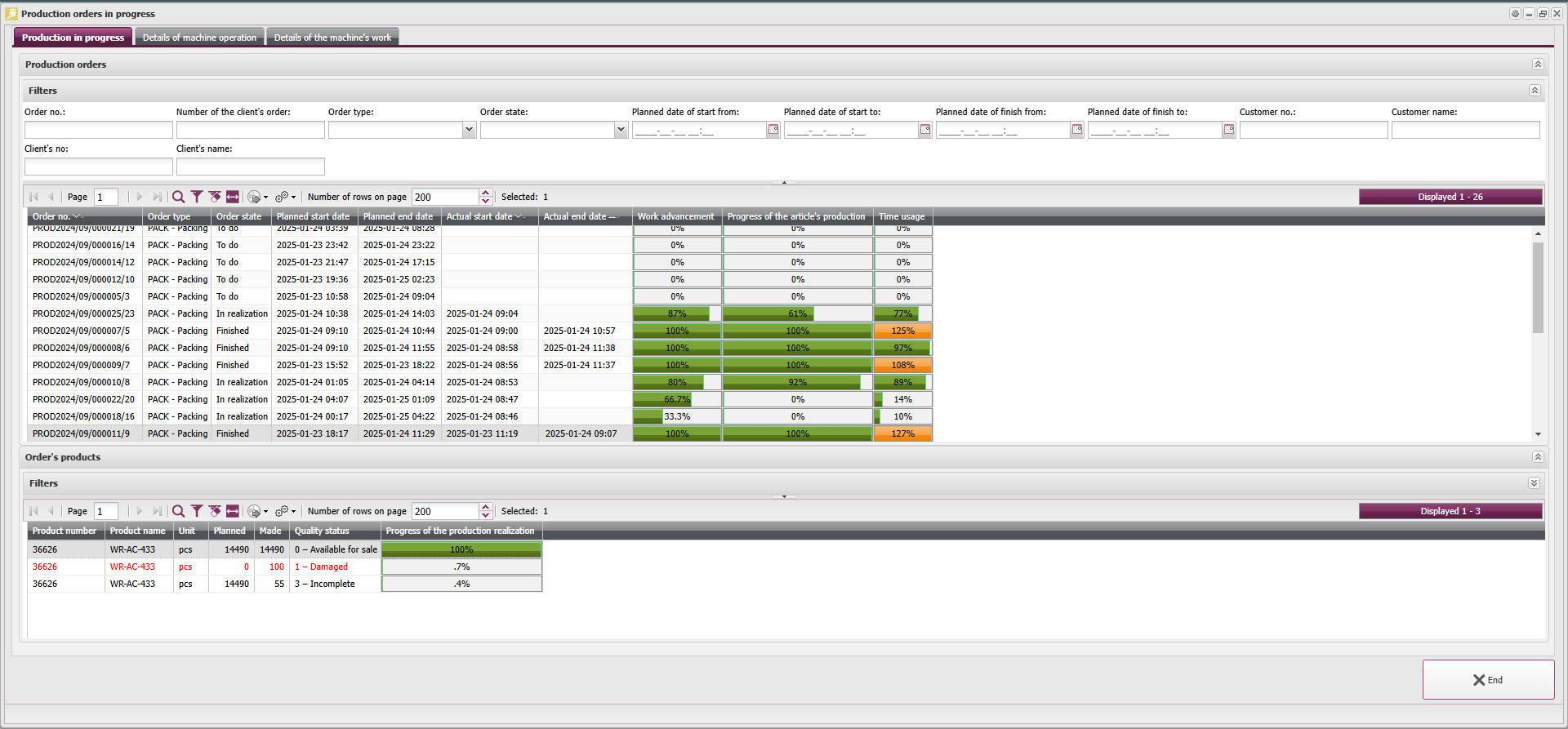

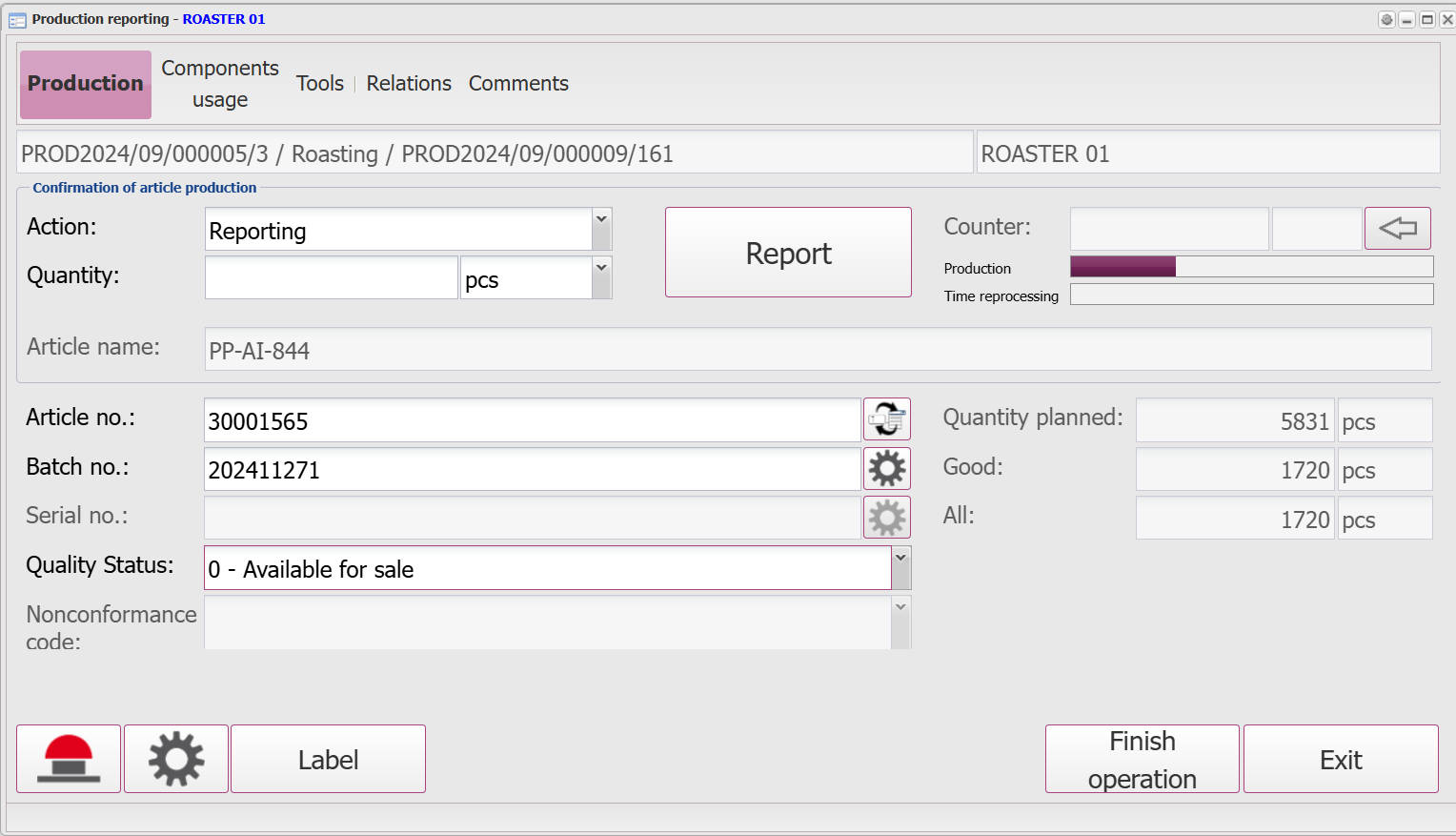

The MES system allows one to effectively supervise production in real time, as it registers and notifies about any deviations from the production realization plan. It allows crucial information to be transmitted between production process participants and coordinates tasks performed by operators, foremen, planners and specialists from the process maintenance department.

What modules and functions are comprised in the MES System (Manufacturing Execution System)

- MRO – Maintenance, Repair, and Operation – the MRO module (CMMS – Computerised Maintenance Management System) supports processing of servicing requests and failure reports, planning of overhauls/inspections and maintenance tasks, manages the stock of spare parts and tools indispensable for production. The module supports servicing logs in terms of planned and realized servicing tasks.

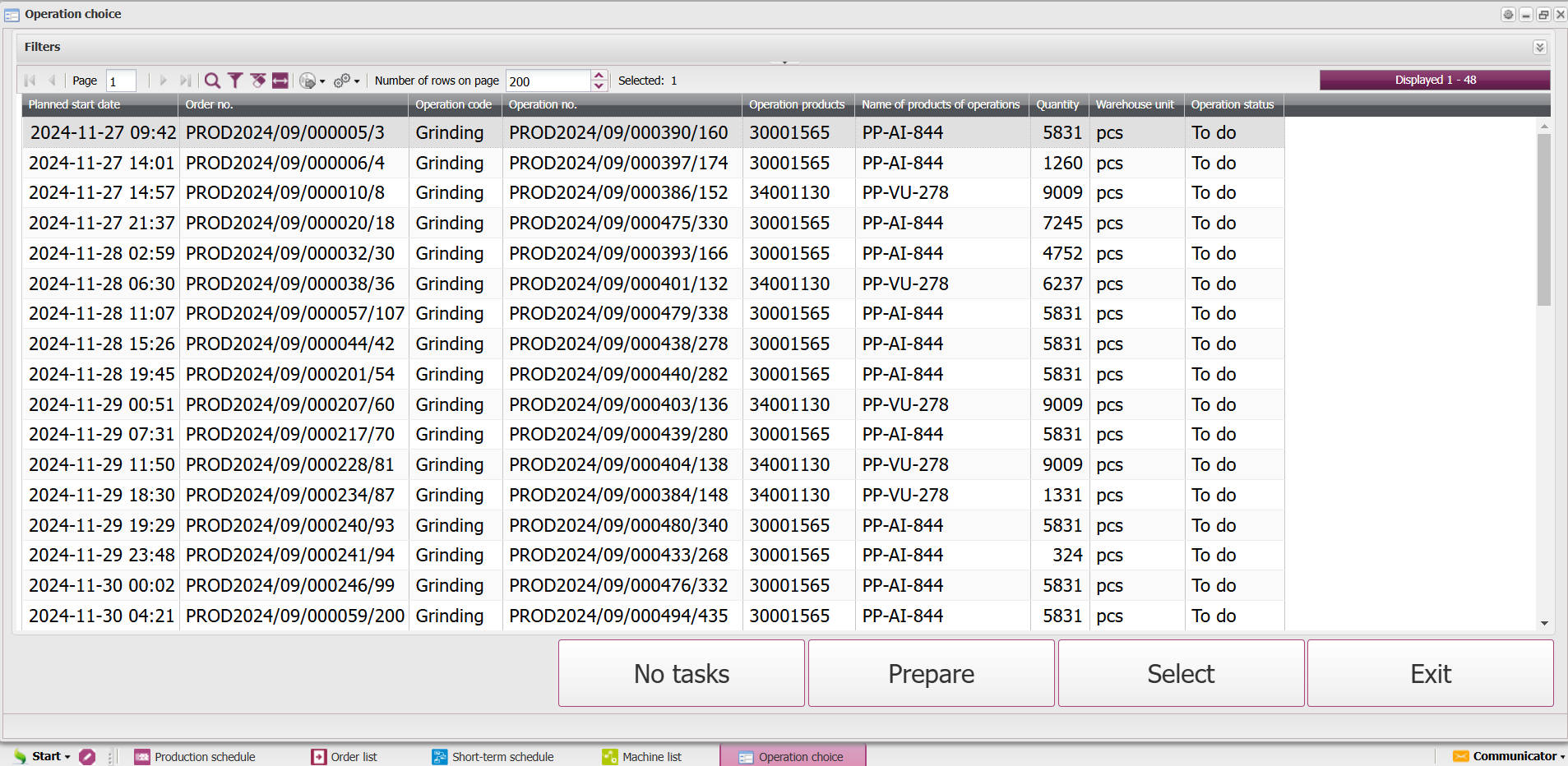

- WIP (Work in Progress) – Production monitoring – the module supports reporting of pre-planned production operations and consumption of raw materials in real time. It displays production progress in time and in quantitative terms, as well as current delays in the production in progress. This software allows the flow of components and finished products to be registered and traced. Thus, a company may maintain optimum stock for the production in progress. The module provides production reports in different perspectives.

- Integration with machines – integration with machinery stock via direct integration with machine controllers or via SCADA-type software. The system supports acquisition of data directly from machines, e.g. acquisition of production counters, machine status or process parameters data.

- IFC ERP – Standard interface – we provide over 30 ready-to-use, fully functional messages for the exchange of data with ERP/MES/WMS-class systems. The following count among the most popular methods of systems integration: file exchange interface – flat files, XML files; ORACLE database interface, WebService.

- Production logistics – use of mobile devices – warehouse operations and management of materials logistics. The module supports operations in the domain of warehousing logistics, both in production and in other processes. The system supports operation via radio terminals equipped with a special application.

- QM – Quality control – the module supports tracing production parameters that impact quality, as well as management of product quality acceptance conditions (AQL). The system allows the user to create customized check lists, supports the sampling process and allows one to attach instructions and documentation. It automatically generates quality reports: SPC, Shewhart control charts.

- Alerts – notification (e-mail, SMS) about various events and conditions, such as, for instance, minimum amount in stock, maintenance-related events or approaching machine overhaul/inspection deadline.

- Technologies / BOM / Recipes – the module allows one to create multi-level bills of materials (BOM). It allows the user to define the full course of a production process, while taking into account interlinks between operations, machines and production work centres, technological process times and retooling times.

Thanks to strict and comprehensive production control, MES software allows one to increase the effectiveness of labour force (registration of performed tasks) and machines (faster reaction to failures and breakdowns). A MES-class system (Manufacturing Execution System) is a program for managing production tasks that allows most processes proceeding in a plant to be realized faster and in a more efficient manner.

Which departments’ tasks are supported by MES systems?

- production department;

- production planning department;

- maintenance department;

- logistics department;

- quality control department;

- continuous improvement department.

What functions and capabilities does the MES system provide?

- management of production orders;

- changeover matrix;

- competence matrix;

- bills of materials (BOM);

- series and batch genealogy and management;

- production materials supply to work stations;

- tracking of the flow of components and finished products;

- failure and defect reporting;

- production scheduling thanks to an additional APS system;

- schedule realization control;

- check lists;

- quality control sampling;

- production reporting, generation of balance sheets and analyses;

- digital documents flow;

- support of HACCP, IFS, SIX SIGMA, 5S, Poka-Yoke;

- cooperation with SCADA and ERP software and with HMI panels;

- operation based on the Lean Manufacturing concept.

Advantages of the Qguar MES system:

- increased productivity of employees and machines;

- reduction of production costs;

- increased production flexibility;

- communication with warehouse ICA components;

- process tracking in real time;

- possibility of early response in emergencies;

- digital documents flow;

- organization of processes and resources;

- integration with external systems;

- possibility of easy and quick modelling of business processes;

- modern and user-friendly user interface;

- traceability;

- production data storage in one place.

FAQ – MES

Answers to the frequently asked questions

Qguar MES can support a wide range of production processes including serial production.

The BPM notation mechanism included in Qguar MES allows for modification of production processes.

Yes. Qguar MES has an APS module to support managers and planners in advanced production scheduling and optimization of production scenarios. Qguar MES can also be integrated with an external APS-class system.

Qguar MES has a “production history” module that registers detailed information on used raw materials, machines, samples taken for inspection, product features, technical parameters and all the people involved in the process (who and when).

Qguar MES allows the user to attach documentation to products/processes and then display information to users, at any point of the process (product cards, quality cards, technical parameters, machine settings, etc.). The user can also attach photographs, videos, text files, PDF files and sound files.

Qguar MES has a functionality to inform users about a variety of events occurring during production or operation of the system. Every alert can trigger an assigned pre-defined reaction of the system. Alerts generated by Qguar MES can be communicated via a wide range of channels such as SMS, email and computer screen messages.

The system offers a detailed inventory of production on the production floor. It registers information on the storage location and exact quantities of all goods in the production facility (material, semi-finished product and final product). Integration with an ERP/WMS system is recommended for tracking of product data based on assumptions of the warehousing management.

QGUAR MES enables the user to define semi-finished product and raw material substitutes by means of BOM options. Products shall be replaced with substitutes of the same functionality, without generating any significant additional costs.

The “machine performance analysis” module in QGUAR MES enables monitoring and acquisition/storage of data concerning machine statuses and resources of the production facility. Analyses of machine operation data logged in the system enable calculation of productivity and OEE (Overall Equipment Efficiency) indicators and production costs (execution of the order).

The system has a tool designed to generate reports, but the user can also export selected data to MS Excel.

In order to support detailed analyses and monitoring of a production process, Qguar MES can interact with a wide range of production equipment such as scales, robots, automated production equipment, CNC machining centres, labellers and many others.

Qguar MES is equipped with mechanisms that enable it to exchange data with other systems implemented by the client, such as ERP- and HMI-class systems.

Qguar MES can use existing SCADA system components and collect information about machines.

A SCADA system does not have to be present. Qguar MES has other functionalities to that support machine status reporting (HMI).