System WMS Pro Qguar

Alter the face of your warehouse with the WMS that belongs to most frequently selected systems with the longest development history in Poland.

- ADR

- Account Settiements

- Forklift Management

- Notifications

- Graphical Indicators

- Interfaces

- RFID

- VOICE

Qguar WMS Pro is a system designed to support warehousing processes in company-owned warehouses or warehouses that rent storage space. The system takes advantage of state-of-the-art solutions in the domains of IT and logistics techniques. With its ability to cooperate with numerous modern external devices, the product undoubtedly belongs to the leading solutions that reach the highest level in the world. Qguar WMS Pro has built-in modules for managing dangerous goods, settling accounts of logistics operations and the optimization of forklift truck operation. The standard version of WMS Pro also offers graphical indicators and a module for configuring interfaces to external systems. The system is ready to work with RFID and Voice technologies.

Qguar WMS (Warehouse Management System) is a piece of modern and complete software for managing a warehouse or a group of warehouses. Long years devoted to work on its development translate into extreme comprehensiveness combined with versatility in adapting to specific lines of trade and their characteristic work requirements, which provides the user with the following features (among others):

- support of barcodes, including the GS1 standard;

- support of the following technologies: RF, RFID, voice picking and light picking;

- management of pallets, forklift trucks and return packaging units;

- realization of the processes of goods picking, stocktaking and cross-docking;

- account settlements of logistic services.

FAQ – WMS

Qguar WMS controls operations carried out in warehouses and manages their performance. Specific tasks with defined scopes of works are created for specific activities carried out in a warehouse. Such approach enables the system to ensure ongoing supervision and reporting of works status.

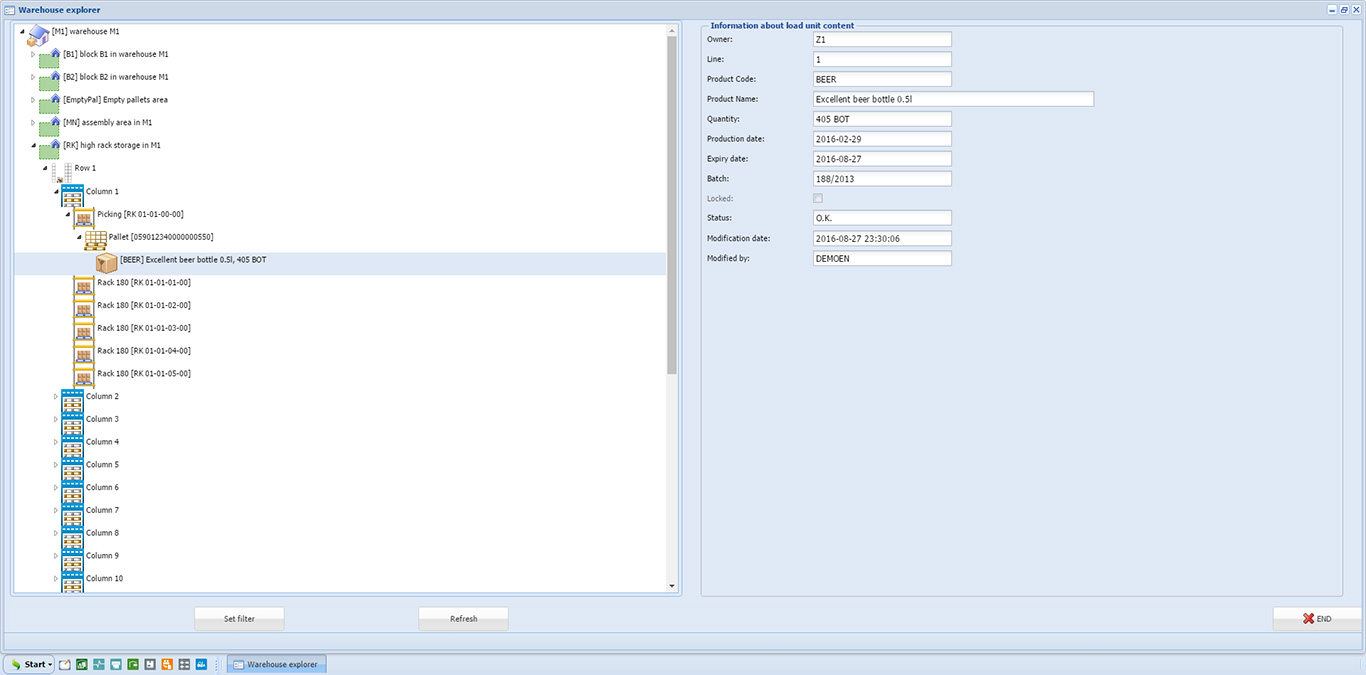

Qguar WMS can manage almost any type of storage. It supports storage of goods without defined rack structure, directly on floors and yards, with or without stacking, but also warehousing on various types of racks, including automated systems.

Storage locations are defined with four coordinates. An example of such a location code is: 4-9-2-1, where:

- first digit (4): row

- second digit (9): column in the row

- third digit (2): level in the column

- fourth digit (1): location at the level.

The system may also use more direct designations of storage locations, in the form of unique ID codes, i.e., combinations of characters and digits.

The system supports the so-called control number functionality, which enables additional validation of operations performed by warehouse personnel in specific storage locations. Control numbers are distributed in a way that prevents their memorization. In case an operation is validated with wireless scanners, control numbers can be printed in the form of a barcode.

Due to the diversity of business sectors and general logistics conditions, deliveries to warehouses may follow different scenarios. It is a very common phenomenon. Therefore, Qguar WMS has been designed to support modelling of the process from the system administrator level through configuration and parameter adjustment.

The system supports both quantity and quality inspection of received goods, enabling the user to check the consistency of a delivery with the corresponding order.

The system enables the user to apply a range of order picking scenarios, depending on product range characteristics, client requirements, applied optimisation algorithms or volume of a specific order (full pallets, pick and pack). These scenarios are developed during system implementation and also at the stage of its operation by the client. The available set of default system parameters and mechanisms enables the user to adjust the existing scenarios and create new processes.

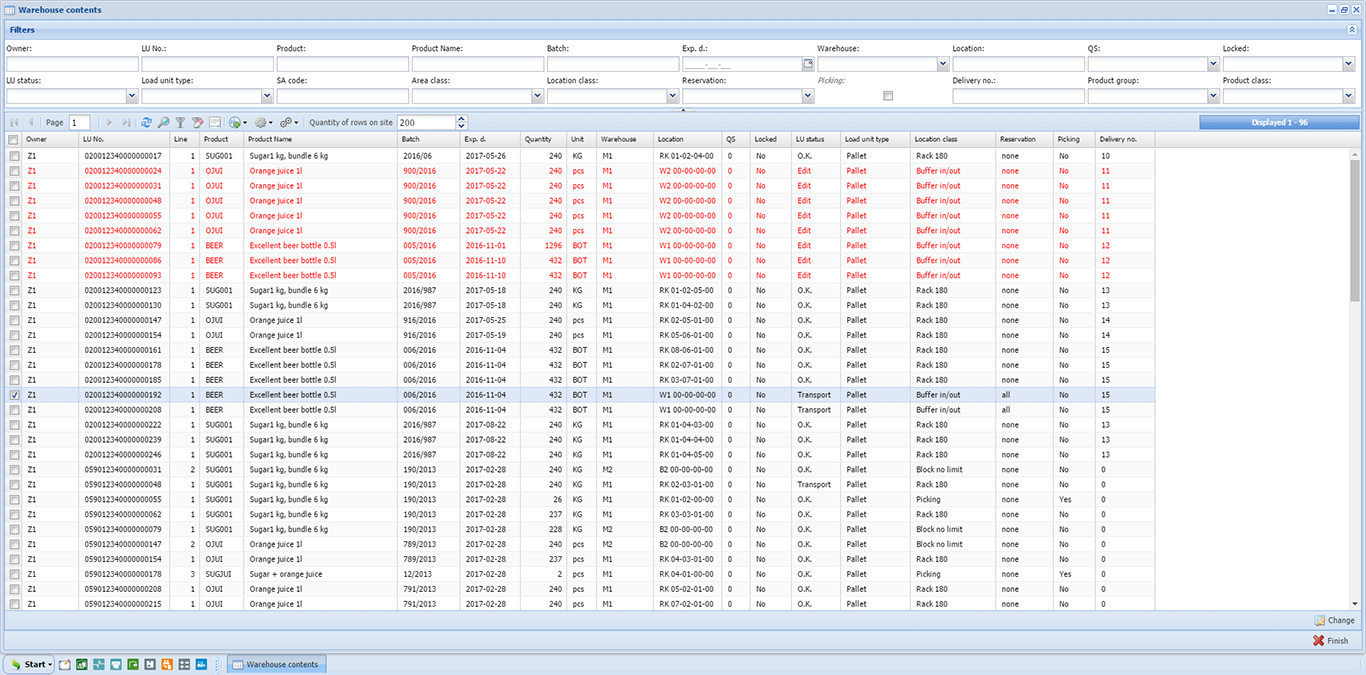

Qguar WMS records production batch numbers and expiry dates. This information can be used in stored goods management processes.

Qguar WMS has a built-in return packaging management module (Qguar RPS), which enables any type of return packages to be managed during receipt, storage and shipment processes. In case the Qguar TMS system is also used, the user can gain a significant advantage by being able to register return packaging in a much broader circulation perspective.

QGUAR is capable of back-tracking a warehousing storage unit (i.e., a pallet). This means that, at any time, the user will be able to determine:

- when and how a particular unit appeared at a warehouse

- when and where it moved within the warehouse

- when it was involved in transfers between warehouses

- which shipments was it used to provide

The history of a unit, combined with the schedule of events enables the involvement of the unit and personnel at all stages of the process to be tracked.

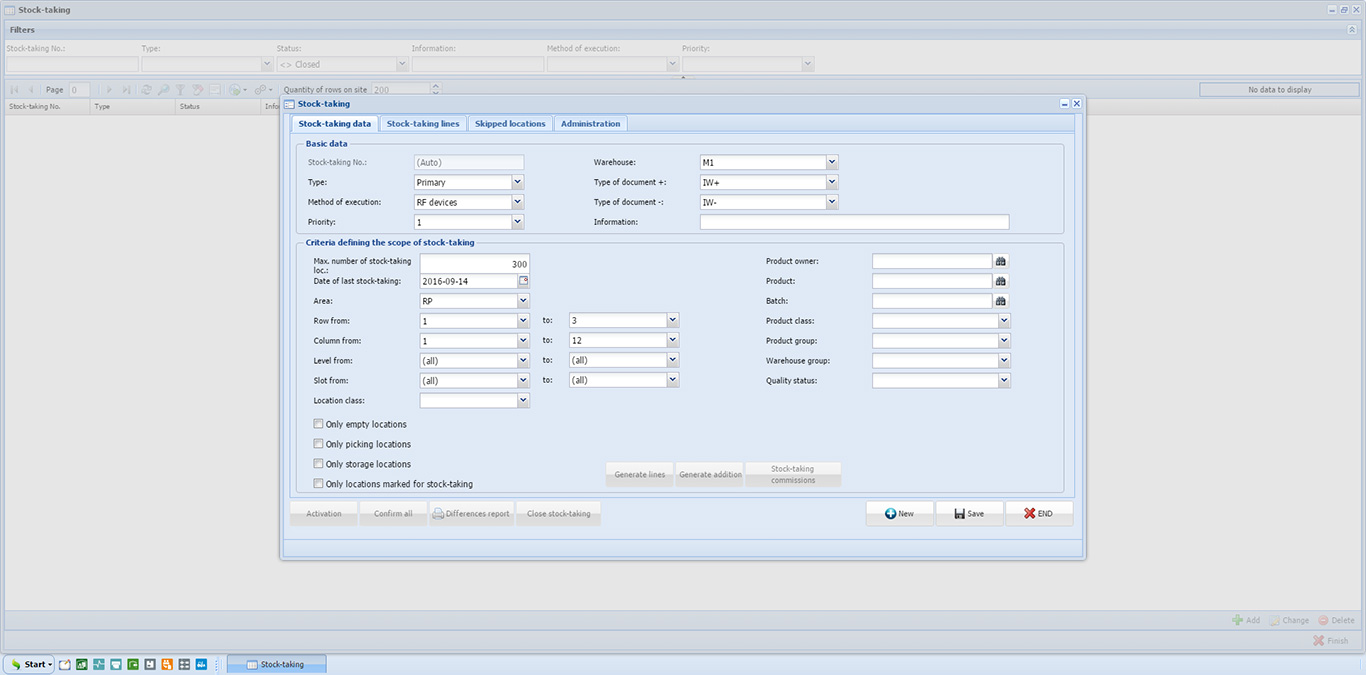

Qguar WMS is able to apply special stocktaking scenarios that result only in minimum disturbances, as only the warehouse sections actually undergoing the stocktaking procedure are blocked.

Qguar WMS supports the management of hazardous goods. The need for ADR storage is growing in many companies. In Qguar WMS, labelling an article as ADR means special restrictions on its storage and transportation, but also an appropriate method of article reporting.

Qguar WMS supports both print-based operation and wireless data exchange in RF technology. Availability of a radio frequency network in a warehouse system allows the operator to have access to the IT system from any location within the warehouse via a personal portable terminal.

Is Qguar WMS compatible with rfid technology ?

Contemporary implementations of IT systems aimed at supporting processes in companies almost always require exchange of data with other systems, very often highly specialized ones. Qguar WMS is a flexible tool that allows for the creation and extension of interfaces to the majority of ERP-class systems available on the market. Quantum has already realized several dozen practical implementations of interfaces to various external systems using different technologies and addressing various levels of difficulty.

An increasing number of logistics facilities are equipped with advanced automated control systems and a range of other equipment to support particular processes. Many elements of warehouse logistics ?? such as stacker cranes, classifiers, internal transportation, pelletizers, labellers, scales and others ? have already been integrated with the Qguar WMS system. Due to the enormous diversity of such equipment and individual profiles of particular projects, integration has to be preceded with a thorough analysis of the equipment specifications provided by the manufacturer.