Visualisation of industrial processes

Graphical presentation of production and logistics processes.

Automation has offered companies the possibility of delivering high quality products and services, while simultaneously reducing the general operational costs. However, employees must still interact with automated systems and make adequate decisions on the basis of acquired data. Without an adequate system for visualisation of industrial processes, a company may find it difficult to derive full benefits that are potentially ensured by automation. Thanks to advanced systems and extensive experience, Quantum may support visualisation of even very atypical processes in your company.

Why visualisation of processes is so important?

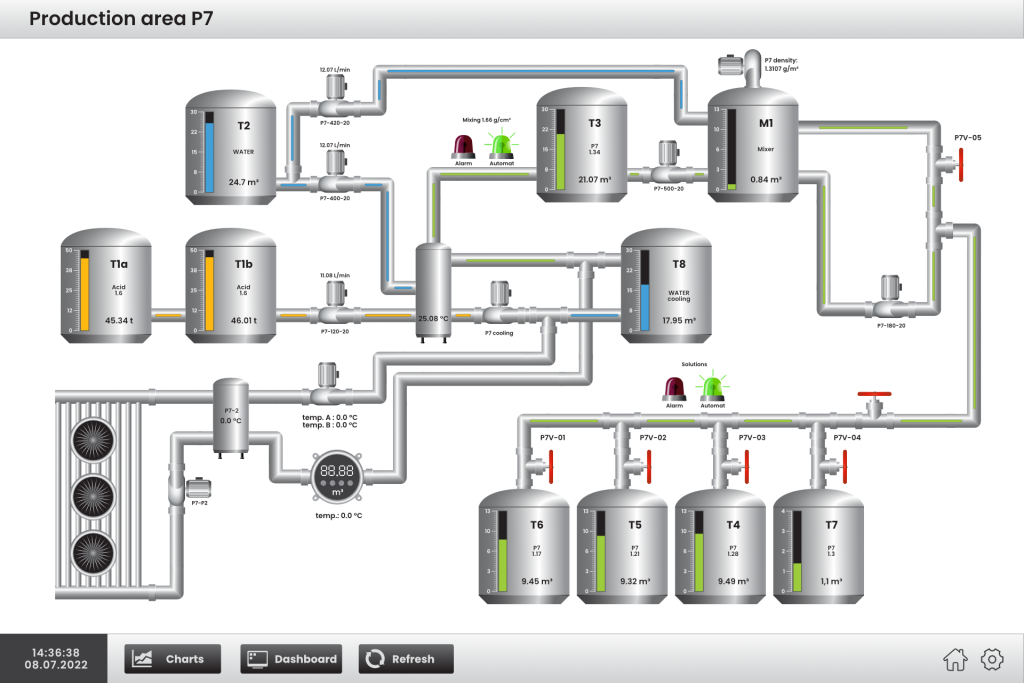

Visualisation of industrial processes is the capability of graphical representation and mapping of equipment, operations and conditions in a plant. Transparent graphic presentation makes it easier for users to control processes and allows for further optimization of various elements, like electric power consumption, for instance. It is assumed that visualisations should facilitate data interpretation and enhance control over events. As a result, such visualisations should contribute to an increase in production efficiency, ensure better overall equipment effectiveness (OEE) and aid quality management. Supervisory Control And Data Acquisition Systems (SCADA) are the most popular solution implemented to create visualisations of industrial processes. Through images generated in the system, SCADA can provide users with lots of important and useful information at once, on just a single screen. The system is capable of visualising a very wide spectrum of processes and phenomena.

Visualisations of industrial processes in different industry branches

Thanks to its universal character, SCADA software has found its applications in numerous domains, which includes among others:

- production (discrete and process manufacturing) – the system allows for specific needs of such branches as food, pharmaceutical or automotive industries;

- power industry – control of electric power generation and distribution;

- water-supply and sewage-disposal networks;

- transport – control of lighting of roads and airfields or control of ventilation systems in tunnels;

- building infrastructure – management of smart buildings.

By means of easily understandable and legible graphics, SCADA illustrates the current status of equipment, entire installations or processes. Visualisations are provided with sets of constantly updated parameters that are crucial for determining the condition or status of a monitored device or process. Among frequently monitored parameters, one finds among others: temperature, level of a liquid in a tank, flow rate, process progress expressed as percentage, and efficiency indexes.

Among objectives that enterprises can achieve through SCADA visualisations, one can list the following:

- simpler interpretation of process data and quick situation assessment;

- intuitive management of large amounts of information;

- improved process control;

- shorter time of reaction to events.

Advantages of visualisations in the SCADA System

The SCADA software supplied by Quantum allows complex systems and processes in an enterprise to be mapped and supported in a simple manner. Visualisations streamline the work of machine operators and supervision personnel as they facilitate adequate decision making and fast reactions. The basic assumption behind SCADA visualisations is transparent and precise mapping of the course of processes and condition of devices that are subject to monitoring.

Among advantages of visualisations created in such a system, one can count the following:

Compliance with the concept of Situational Awareness – The SCADA system takes advantage of the assumptions of the Situational Awareness, in order to facilitate interpretation of visualisations. This means that visualisation design is aimed at presenting processes to be visualised in as simplified form as possible. The user should receive only the information that he/she really needs to get to perform his/her work. Unification/standardisation of applied colour schemes and high prominence of anomalies is another postulate of the SA concept that facilitates work.

Simplicity of creation – The SCADA software offered by Quantum includes a rich library of templates and pre-defined screens. Visualisations may be created through combination of ready-made objects and ascription of appropriate parameters to such objects. There is no need for any software development works in the entire process.

Personalization – Strong focus on the information needs of a particular work place. Thanks to intuitive wizards, the scope and level of details of information to be presented can easily be adapted to the requirements of a user, no matter, whether the user is a machine operator, a shift supervisor, a maintenance technician or a production manager.

Operation via a web browser – As the system supports the HTML5 technology, SCADA visualisations are available on every device with a web browser, be it a personal computer, a tablet or a smartphone. Users may freely communicate with the system by means of every such device.

An alternative to the SCADA system

For some companies, it may result excessively costly to implement an advanced SCADA system. It does not mean, however, that they have to give up all the functions offered by the system, including visualisation. Quantum also offers alternative solutions based on the technology of smart industrial sensors. They allow one to take advantage of the most important functions of SCADA systems even when the budget is considerably limited. Thanks to high scalability, such solutions are more than suitable for the creation of pilot versions. Thanks to such versions, the client may verify in a short time, whether the offered scope of functions is sufficient for his needs.