System APS Qguar

Automatic scheduling of production that takes into account available resources, established priorities and objectives.

- Notifications

- Graphical indicators

Qguar APS (Advanced Planning & Scheduling) is a perfect piece of software designed to support managers and planners in advanced production scheduling and optimization of production scenarios. Qguar APS is equipped with optimization algorithms, based on artificial intelligence (hybrid methods, constraint programming), that allow one to plan production in a manner that ensures orders are realized in a possibly short time at the lowest cost, while ensuring the highest possible efficiency of production machines and the shortest down-times. Thanks to Qguar APS, the planning and scheduling of production orders proceed efficiently, while human errors are avoided. The interface of Qguar APS is simple to operate and implements standards generally recognized for software with graphical HMIs.

Qguar APS (Advanced Planning & Scheduling) is a modern tool, aimed primarily at supporting planning and optimizing production scenarios. This solution translates into faster realization of orders thanks to higher efficiency of machines, lower costs and fewer downtime events. In a slightly broader context, the program capabilities include:

- advanced production planning and scheduling;

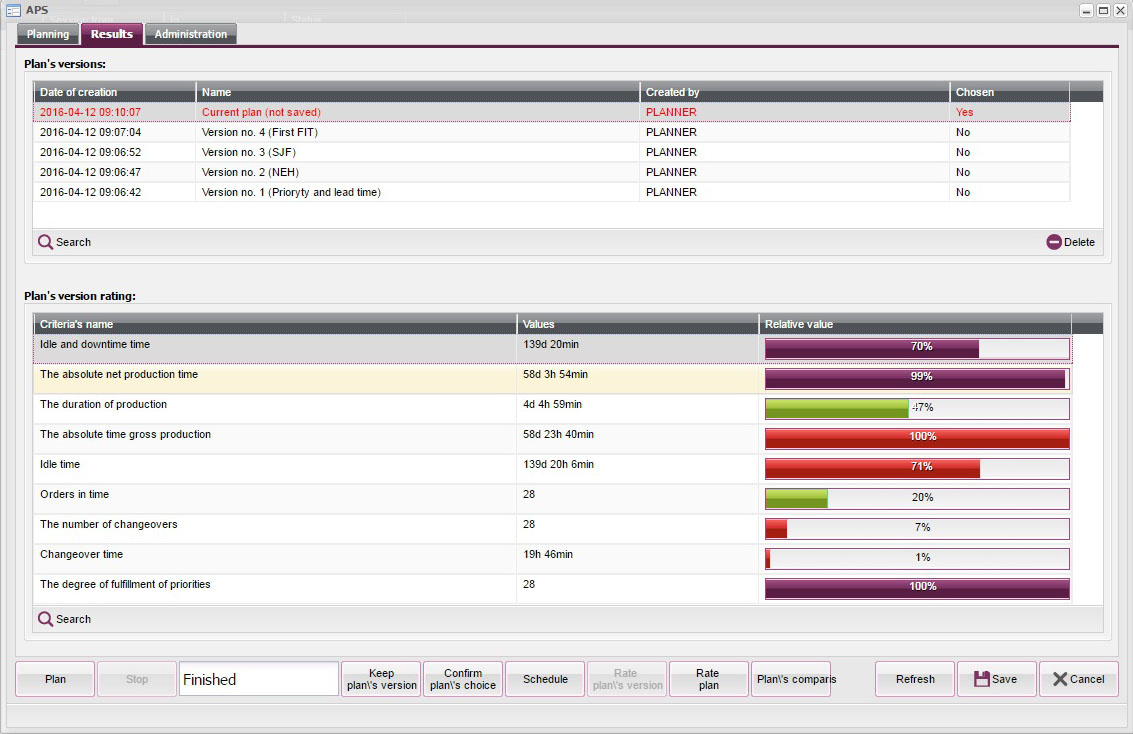

- production plan assessment;

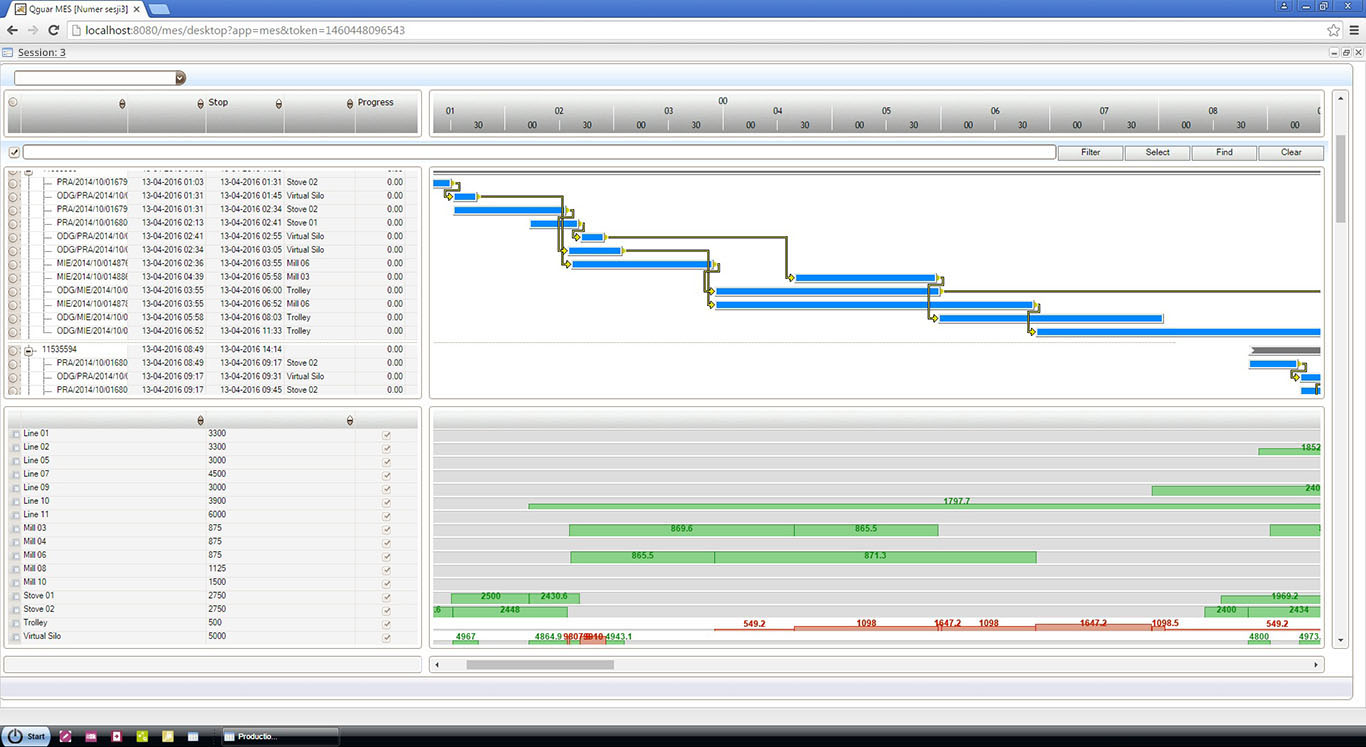

- analysis of production capacity;

- reduction of order realization time;

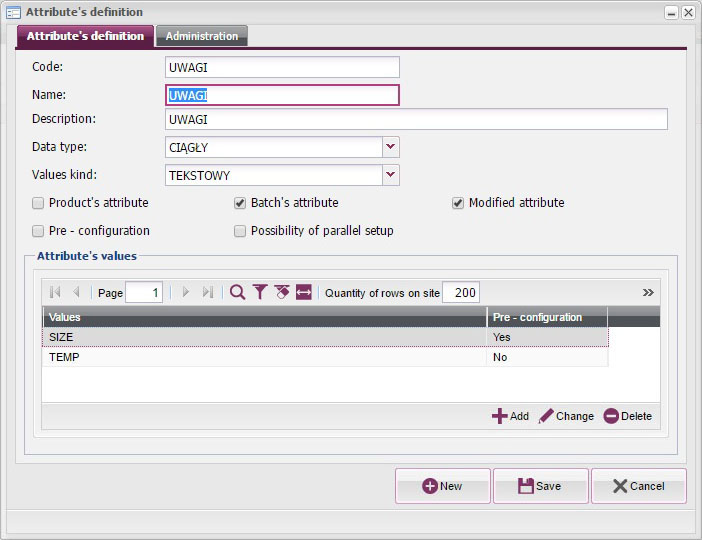

- management of resources, calendars and downtime events.

FAQ – APS

Answers to the frequently asked questions.

You should start thinking about implementing the Qguar APS system when managers and production planning people feel the need for support in advanced scheduling of orders and optimizing order handling scenarios.

The optimization algorithms of Qguar APS enable you to plan orders in a way that ensures their total delivery time is minimized, which in turn increases productivity and reduces unit production costs.

The APS system enables precise scheduling of production orders and supports practical implementation of the “just-in-time” concept through integration with ERP class systems. Thanks to full synchronization of provisioning and production, we are able to reduce stocks and optimize supply processes.

Yes. Choosing Qguar APS as an extension to your functional ERP system opens new opportunities to reduce production and provisioning costs, as well as to improve personnel efficiency. Implementation of the APS system along with MES and ERP class systems results in a significant increase in performance and reduces the need for personnel to provide process supervision and servicing.

Qguar APS has an algorithm that minimizes the average delay, counted from delivery date. This algorithm takes into account priority levels allocated to orders and plans the realization sequence according to the priority level.

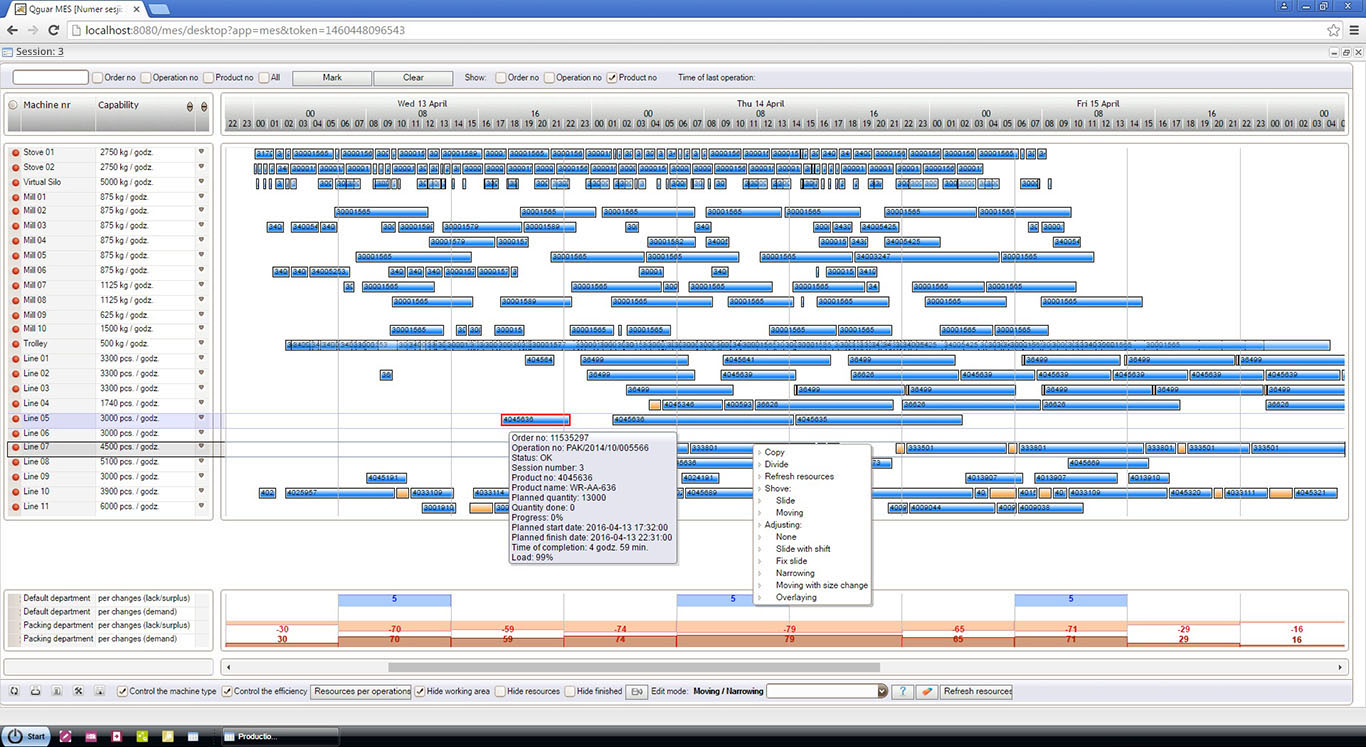

There are three ways of presenting a production process in Qguar APS:

- Gantt graph for production tasks in particular positions;

- Gantt graph for realization of production orders in time;

- Production posts loading time graph.

Qguar APS has a functionality that allows several alternative versions of a production plan to be compared. This enables a production planner to make decisions concerning, for example, maximum loading of particular resources.

ERP systems are able to exchange data necessary to illustrate production plans. After optimization, the master system receives the selected production order realization scenario, with starting and completion dates for all operations, allocation of resources and due dates for all resources, materials, semi-products, etc.

Contact Form

Company

Contact

- +48 (12) 646 98 00

- +48 (12) 646 98 02

- info@quantum-software.com

- quantum-software.com